OUR HONOR

Screw Barrel For Extrusion Machine Industry knowledge

How do the specifications of screw barrel for extrusion machines impact material processing efficiency?

The performance of extrusion machines greatly hinges on the specifications of their screw barrel configurations, impacting material processing efficiency in various ways:

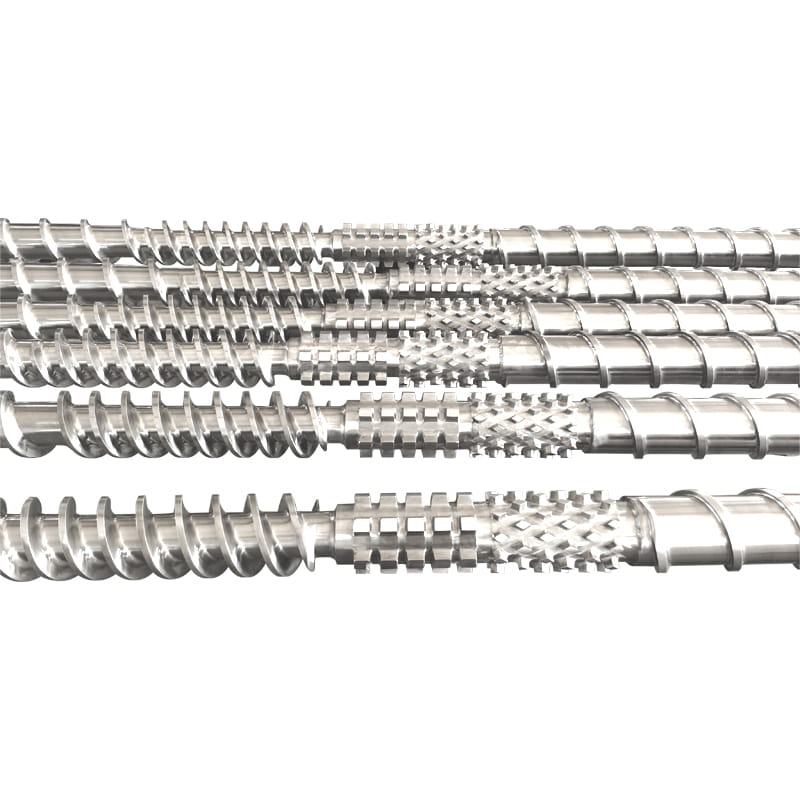

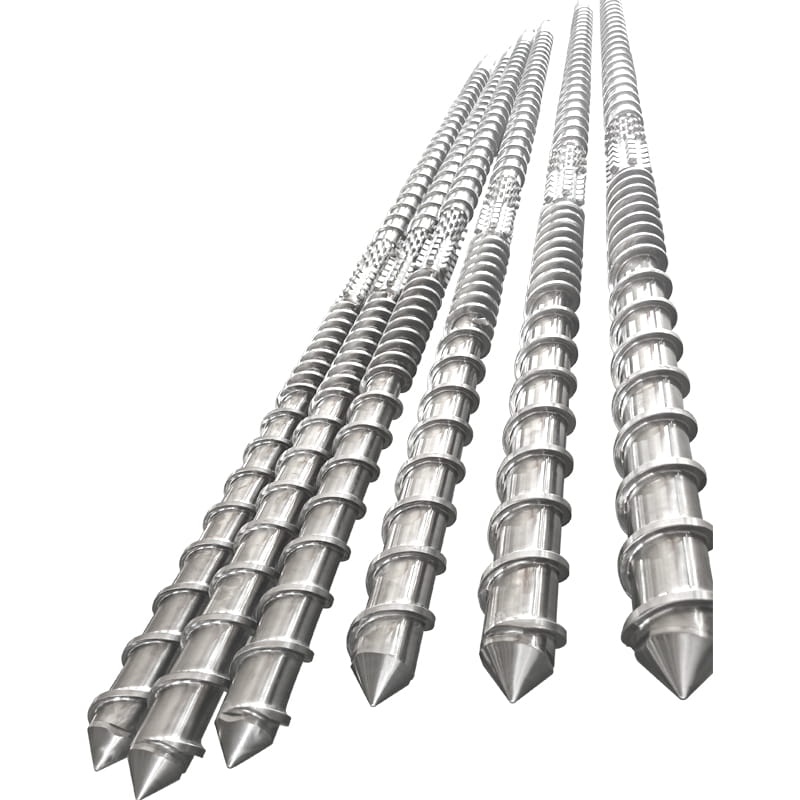

Screw Configuration: The geometry of the screw, encompassing aspects such as flight depth, pitch, and channel geometry, dictates how effectively the material is conveyed, compressed, melted, and mixed. Well-designed screws ensure consistent material flow and homogeneity, thereby reducing processing interruptions and enhancing throughput.

Barrel Dimensions: Both the length and diameter of the barrel influence residence time, heat transfer, and material compression. Properly sized barrels facilitate adequate melting and mixing of the material, preventing overheating or degradation. Optimal barrel dimensions contribute to uniform melt quality and overall processing efficiency.

Material Choice and Coatings: The selection of materials for the screw and barrel, alongside potential coatings, impacts wear resistance, corrosion resistance, and thermal conductivity. High-quality materials and coatings enhance longevity, minimize frictional losses, and sustain consistent performance, ultimately improving processing efficiency.

Compression Ratio Optimization: The compression ratio, a measure of feed zone channel depth relative to metering zone channel depth, governs material compression and melting intensity. Fine-tuning the compression ratio ensures efficient material plasticization and homogenization, maximizing throughput and minimizing energy consumption.

Screw Speed and Torque Control: Rotational speed and torque significantly influence material conveyance, melting, and mixing rates. Adjusting screw speed and torque optimizes processing parameters, balancing throughput requirements with energy efficiency and ensuring product quality consistency.

Precise Temperature Management: Maintaining uniform temperature within the barrel is essential for preserving desired material viscosity and flow properties. Effective heating and cooling systems ensure even temperature distribution, guarding against overheating or underheating of the material and bolstering processing efficiency.

Melt Pressure and Flow Dynamics: Melt pressure and flow characteristics directly impact extrudate quality and processing stability. Carefully specified screw barrel configurations minimize flow irregularities, surging, and melt fractures, thereby boosting overall processing efficiency.

Enhanced Mixing Capabilities: Specifications of screw barrel configurations influence material mixing and dispersion during extrusion, especially in applications involving additives or colorants. Improved mixing promotes uniform additive distribution and enhanced product consistency, elevating both processing efficiency and product quality.

In summary, the specifications of screw barrel for extrusion machines significantly influence material processing efficiency. By optimizing screw design, barrel dimensions, material selection, compression ratio, screw speed, temperature control, and mixing capabilities, extrusion processes can be fine-tuned for maximum productivity, energy efficiency, and product quality.

The performance of extrusion machines greatly hinges on the specifications of their screw barrel configurations, impacting material processing efficiency in various ways:

Screw Configuration: The geometry of the screw, encompassing aspects such as flight depth, pitch, and channel geometry, dictates how effectively the material is conveyed, compressed, melted, and mixed. Well-designed screws ensure consistent material flow and homogeneity, thereby reducing processing interruptions and enhancing throughput.

Barrel Dimensions: Both the length and diameter of the barrel influence residence time, heat transfer, and material compression. Properly sized barrels facilitate adequate melting and mixing of the material, preventing overheating or degradation. Optimal barrel dimensions contribute to uniform melt quality and overall processing efficiency.

Material Choice and Coatings: The selection of materials for the screw and barrel, alongside potential coatings, impacts wear resistance, corrosion resistance, and thermal conductivity. High-quality materials and coatings enhance longevity, minimize frictional losses, and sustain consistent performance, ultimately improving processing efficiency.

Compression Ratio Optimization: The compression ratio, a measure of feed zone channel depth relative to metering zone channel depth, governs material compression and melting intensity. Fine-tuning the compression ratio ensures efficient material plasticization and homogenization, maximizing throughput and minimizing energy consumption.

Screw Speed and Torque Control: Rotational speed and torque significantly influence material conveyance, melting, and mixing rates. Adjusting screw speed and torque optimizes processing parameters, balancing throughput requirements with energy efficiency and ensuring product quality consistency.

Precise Temperature Management: Maintaining uniform temperature within the barrel is essential for preserving desired material viscosity and flow properties. Effective heating and cooling systems ensure even temperature distribution, guarding against overheating or underheating of the material and bolstering processing efficiency.

Melt Pressure and Flow Dynamics: Melt pressure and flow characteristics directly impact extrudate quality and processing stability. Carefully specified screw barrel configurations minimize flow irregularities, surging, and melt fractures, thereby boosting overall processing efficiency.

Enhanced Mixing Capabilities: Specifications of screw barrel configurations influence material mixing and dispersion during extrusion, especially in applications involving additives or colorants. Improved mixing promotes uniform additive distribution and enhanced product consistency, elevating both processing efficiency and product quality.

In summary, the specifications of screw barrel for extrusion machines significantly influence material processing efficiency. By optimizing screw design, barrel dimensions, material selection, compression ratio, screw speed, temperature control, and mixing capabilities, extrusion processes can be fine-tuned for maximum productivity, energy efficiency, and product quality.

عربى

عربى